4 Mins Read

Buenos Aires-based Stämm Biotech recently closed a $17 million Series A round to scale its 3-D printing bioreactors aimed at the global cultivated meat sector. This brings the startup’s funding to $20 million. The new investment will be used to double the company’s headcount and refine its micro-fluidic bioreactor developments. The smaller bioreactors could reduce the required size of a bio-manufacturing facility significantly.

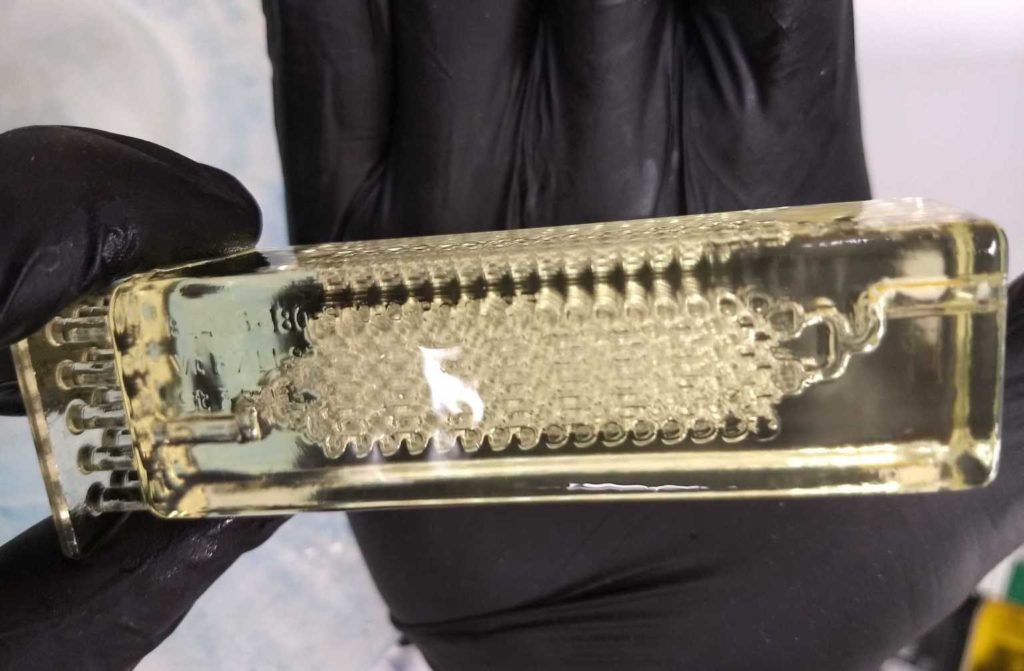

Stämm, which was founded in 2016, is currently developing a desktop-sized bioreactor powered by 3D printing methodology. Replacing giant sterilised tanks with portable units capable of printing complex channels for oxygen and nutrient delivery allows for the possibility of a range of uses including pharmaceutical and cultivated meat applications.

Philip Broenniman, co-founder and Managing Partner at Varana Capital which led the round, said the startup’s digitization technology was a huge draw. “With this most recent fundraise, we, along with the balance of investors, are excited to be a part of Stämm’s mission to decentralize the biotech industry, to digitize bio-manufacturing in the cloud, and to enable democratized access to biotechnology products.”

In a show of confidence, a number of existing investors doubled down in the round including Draper Associates, SOSV and Grid Exponential. Decarbonization Consortium, New Abundance, VistaEnergy and Serenity Traders also participated.

Out with the old?

Traditional industrial bioreactor units are large. They feature vast stainless steel tanks that grow the desired final product. Inside, the contents are constantly stirred, kept at the optimum temperature, and fed with oxygen until they reach maturity. The process is costly and input-sensitive. Stämm aims to remove the need for tanks and stirring by replacing the process with 3D-printed microchannels that supply oxygen and nutrients to cell mediums as they grow. The entire process becomes smaller, self-contained, and self-perpetuating.

“We detected this breach between the will to develop a biological product and the abilities of tools that were out in the market,” Yuyo Llamazares Vegh, co-founder and CEO of Stämm told TechCrunch. “That inspired us to take ownership of this problem.”

Biomanufacturing cannot occur without bioreactors. Stämm says it its mission is a simple one: to make the necessary equipment smaller and more straightforward using micro-fluidics.

“Stämm mimics nature’s use of laminar flow to down-size a whole biotech facility into an all-in-one, plug & play desktop unit,” Llamazares Vegh has previously explained. “Our focus is to decentralize bioprocesses and democratize access to biotechnology products, thus freeing our partners to focus on the disruptive discoveries that make an impact on people’s life.”

Securing partnerships

As the cultivated meat industry gains momentum, this methodology has the potential to be applicable. However, in terms of scale and cost, there are wrinkles to iron out. Stämm’s tech currently operates on a far smaller scale than conventional industrial bioreactors. At present, it can offer up to 30 litres of capacity, though scale-up to 5,000 litres has been cited as possible. Alongside, the relative newness of the development means that full commercialisation is a way off.

“We are exploring at this stage, understanding diverse business models and interaction with clients,” Llamazares said.

The company is focused on securing of strategic collaborations an initial priority, which will allow for a move towards “pilot-scale” later this year. It says it currently has one confirmed partner on board (a Pharmaceuticals company), with another five in negotiations.

A circular transition

Llamazares Vegh says that Stämm designs their solutions with a circular economy logic. By using their platform, their partners will be able to transition to a productive biotech industry infrastructure that is far more efficient. He reckons they will see savings in terms of reduced energy consumption, decereased material requirements and lower overall carbon footprints.

Bringing this technology closer to more people is key, he adds, “if we want to start taking advantage of non-traditional biomass and its derivatives, which has the potential to reduce the carbon footprint of the industry and develop the industrialization of new biological platforms by leveraging local genetic resources.”

The future of food

Scaling up for commercial launch is on the minds of numerous meat industry-disrupting cultivated companies. Despite only Singapore currently giving the go-ahead for the sale of cell-based products, plenty of startups have been investing in industrial-scale facilities and bioreactors.

Upside Foods notably finished construction of its Californian Engineering, Production, and Innovation Center (EPIC) in November last year. It recently opened the facility for consumer tours, to offer insight into how cultivated meats are made. The company hopes this will create understanding and buzz ahead of regulatory approval, which it is still waiting for. Upside had hoped to be given the green light by the close of 2021 but was left wanting.

Last month, it was revealed that Israel’s Aleph Farms had relocated to a new 65,000 square foot location that will allow it to scale its cultivated beef steaks. Completion of the new plant was funded, in part, by a $105 million Series B round. The company hopes to gain approval for commercial sale by the end of 2022.

Lead photo from Canva.