Wildtype’s New Facility Can Make 200,000 Pounds Of Cell-Based Salmon Per Year

4 Mins Read

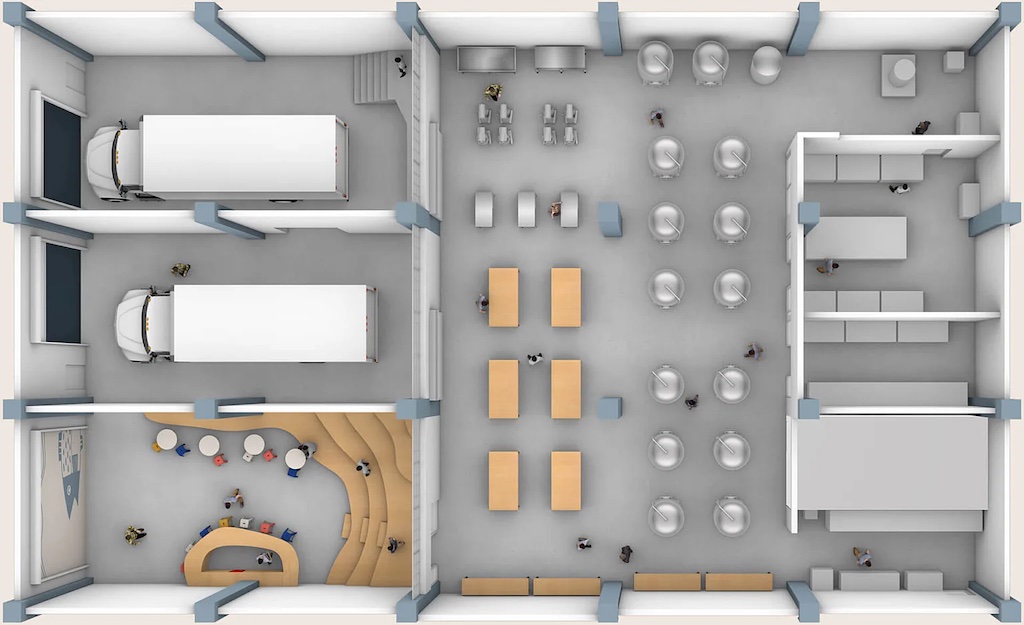

Wildtype, the startup cultivating sushi-grade salmon, is about to begin operating a brand new pilot production facility. Slated to open in the coming months, the factory has a maximum capacity of 200,000 pounds of cell-based seafood. Next to the production site is an education and sushi bar for cultured fish tastings.

Calling it a “first-of-its-kind facility”, Wildtype will soon open its doors to its pilot plant in the next 2-3 months. Located in San Francisco, the space houses both its factory-side operations and room for tasting and education events.

Once opened, the factory’s near-term capacity is around 50,000 pounds of cell-based seafood. But at maximum, it’ll be able to churn out more than 200,000 pounds.

Showcasing the ‘promise and wonder’ of cellular agriculture

Designed by award-winning architect Shuo Zhai, the concept is designed to showcase the future of protein production. On one side is its cell-based seafood manufacturing area. Next to it, there’s a sushi bar and an education centre, fitted with bleachers for visitors to sit and learn.

The facility will be a place where the public can learn about this fascinating new technology.

Aryé Elfenbein, Co-Founder, Wildtype

“Global demand for seafood is outpacing supply, so the status quo needs to change. Our pilot plant will showcase the promise and wonder of growing fish fillets using cell cultivation,” commented Aryé Elfenbein. Elfenbein co-founded Wildtype in 2019 with Justin Kolbeck.

“In addition to being designed to shorten innovation cycles and facilitate the scaling of food production, the facility will be a place where the public can learn about this fascinating new technology.”

Glass doors separate the tasting area from the production floor—everything is transparent to show people how seafood can be cultivated directly from cells. Visitors won’t just be able to taste seafood at the sushi bar, but can also watch documentaries about cell-based technology. Science students from local schools around the area might even be able to tour the place, says Wildtype.

Read: Cell-based meat market to hit $25 billion by 2030, McKinsey predicts

Getting cell-based sushi-grade salmon to supermarkets

With its pilot production plant months away from being operational, Wildtype’s next focus is scaling up. The startup has big plans—it wants to bring its cell-cultured sushi-grade salmon all the way to retail chains.

“We’re thrilled to soon be delivering delicious, clean, and nutritious sushi-grade salmon to our launch partners,” wrote Kolbeck in a blog post. “What comes after that is making Wildtype salmon available to consumers at places like Costco, Trader Joes, and Walmart.”

In the near-term, Wildtype will still be focused on foodservice. It started taking pre-orders from chefs in the Bay Area late last year. But the pilot plant will be a big part of helping the company get to its next target. It provides room for error, testing and improving cost-efficiency.

“Once we launch Wildtype sushi in grocery stores, there is no room for stock outs, missed deliveries, or quality issues, and so our pilot production process needs to be fully stress-tested before we can move up in scale,” continued Kolbeck.

“We’re rising to this challenge and are excited to introduce our products to the public very soon.”

Read: Study — 78% consumers in Singapore willing to try cell-based seafood

A solution built for cities

In the post, Kolbeck explains that its production plant was built with cities in mind. For import-reliant cities, this presents a key food resilience solution to defend against supply chain shocks.

“It work[s] well in an industrial building right in the middle of a bustling city. This means that our food can be produced much closer to the population centres where it’s consumed. Fewer food miles means a greener and cleaner supply chain,” the co-founder explained.

Facilities like this proves that we can grow the highest quality seafood anywhere in the world.

Justin Kolbeck, Co-Founder, Wildtype

Aside from improving food security, Wildtype says the plant demonstrates a far more sustainable and ethical way for animal protein production.

“Building demonstration-scale facilities like this proves that we can grow the highest quality seafood anywhere in the world: urban or rural, temperate or tropical,” said Kolbeck.

“We have already shown that we can build a pilot facility right in the heart of San Francisco that can satisfy most of, if not all, the salmon sushi sold in the city. If we can do it with one facility on a microbrewery footprint, we believe we can reproduce this model all over the country, and indeed around the world.”

All images courtesy of Wildtype.