Tufts University Banks on Open-Access Model to ‘Transform’ Cultivated Meat Industry

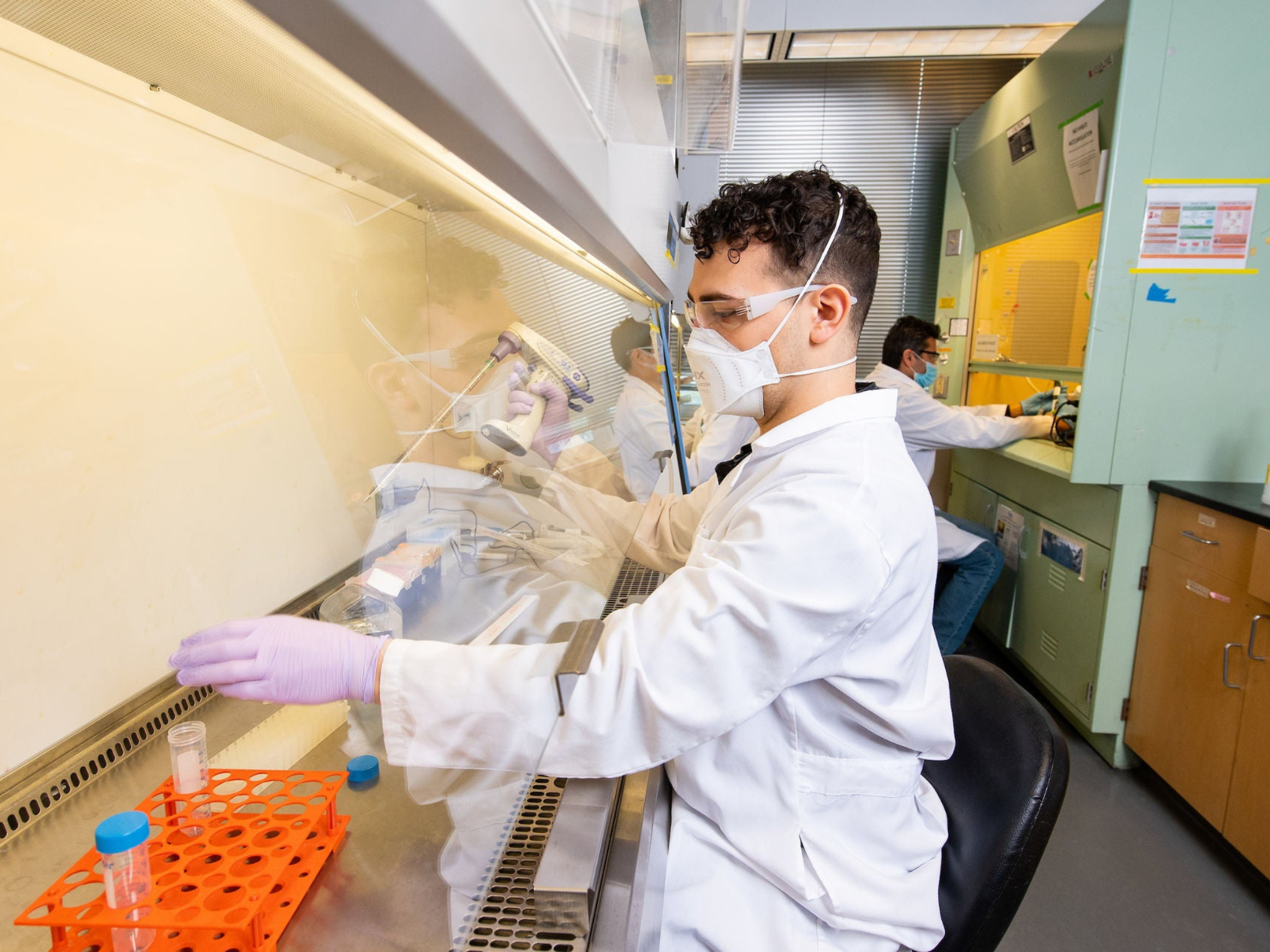

Backed by a $2.1M state grant, Tufts University will open a future food innovation hub this year, with an open-source cell bank for cultivated meat research.

An upcoming centre at Tufts University’s Medford campus offers “truly transformational potential for cultivated meat” through an open-access cell bank that could solve some of the industry’s biggest bottlenecks.

Set to open later this year, the Foodtech Engineering for Alternative Sustainable Technologies (FEAST) hub is supported by a $2.1M grant from the MassTech, Massachusetts’s public innovation agency.

It will bring together scientists, businesses and policymakers in a bid to bring future-friendly foods to market faster. The highlight of its effort is the new cell bank born out of a partnership between the Tufts University Center for Cellular Agriculture (TUCCA) – where the hub will be located – and the Good Food Institute (GFI).

The two have teamed up to salvage the IP of defunct cultivated meat firms and are making them publicly available for researchers. In October, GFI acquired eight bovine cell lines and two serum-free media formulations from SciFi Foods (which shut down in 2024), which will be validated and stored in Tufts’s cell bank.

The university played a “critical role” in making these resources available to the public, marking a “major step forward” for open-access innovation in the alternative protein sector, according to Elliot Swartz, senior principal scientist of cultivated meat at GFI. “The open cell bank has truly transformational potential for cultivated meat,” he told Green Queen.

“By housing academic and recovered industry cell lines in an accessible repository, researchers can build on high-performing, well-characterised cell lines across species, saving millions of dollars, shaving years off typical R&D timelines, and creating the kind of shared scientific foundation that has driven progress in biotechnology, pharmaceuticals, and beyond.”

‘We didn’t know who would show up’

Cell lines are a specific type of cells that can be grown indefinitely in a solution containing nutrients or media. These can be used to produce cultivated meat, and GFI and Tufts are aiming to obtain and broadly these components.

By making them widely available, they can rescue years of efforts and millions of dollars’ worth of R&D, which would otherwise be lost after company closures. SciFI Foods is a prime example. The firm raised over $40M to develop a hybrid burger featuring 10% cultivated meat. As investors flocked away from the sector, the startup became one of several casualties.

Its assets were being sold at an auction last year. “We didn’t know who else might show up for the auction, but collectively agreed it would be a shame for SCiFI’s technology to get locked in a box somewhere, so we were excited that GFI decided to bid,” said Meera Zassenhaus, director of communications for TUCCA.

The cell lines bought by GFI include SciFi Foods’s three most commercially developed beef cell lines, all modified by the gene-editing technology CRISPR and adapted to grow in scalable, single-cell suspensions.

This means the cells grow while floating freely in the solution, forming a slurry-like mass, in contrast to most cells, which require something to attach to and be scraped off of. This is “the most exciting feature” about SciFi’s cell lines, according to Tufts associate professor Andrew Stout, who is leading the cell bank effort.

“[It] allows for simple, large-scale production in bioreactors, making them the first such livestock-based cell lines broadly available to the field,” he said.

“There’s a lot of research that can be done about figuring out how to make other cell lines grow in single-cell suspension,” said Natalie Rubio, executive director of the Cellular Agriculture Commercialization Lab, which is leading the banking and distribution of the cells. “The cells we acquired will open the door for some more scalable research, like bioreactor optimisation.”

Tufts hub can save costs and time with ‘much-needed’ shared infrastructure

The Cellular Agriculture Commercialization Lab is now raising funds to build out its infrastructure and develop additional cells from a range of livestock and harvested animal species. These include bovine, mackerel and pork lines.

“We are essentially composting intellectual property, or IP, from an individual start-up and transforming it into a public good to benefit the entire field,” said Zassenhaus. “This model of IP reuse makes sense for all kinds of technologies, even beyond alternative proteins, especially as climate tech broadly faces a contraction in funding.”

Aside from the cell bank, the FEAST centre will include shared-use prototyping and scale-up research facilities, an incubator lab space, and a test kitchen.

“The pilot facility and analytical lab offer a shared space for researchers and startups from Tufts and beyond to conduct scale-up experiments, test new bioprocesses, and analyse end products under one roof, filling a major infrastructure gap in the US and around the world,” said Swartz.

“This shared infrastructure can help research labs and startups save money on equipment costs, save time by preventing the need to partner with multiple different contract organisations, and enable open-access scale-up and product development research that has been lagging behind cell line and media development,” he added.

Swartz said the launch of the future food innovation hub will provide “much-needed shared infrastructure” for the cellular agriculture ecosystem.

“As an organisation focused on unlocking open-access research and advancing R&D, GFI sees this MassTech-funded hub as a powerful proof point that strategic public investment can accelerate scientific progress, derisk innovation, and strengthen the cultivated meat field as a whole.”