3 Mins Read

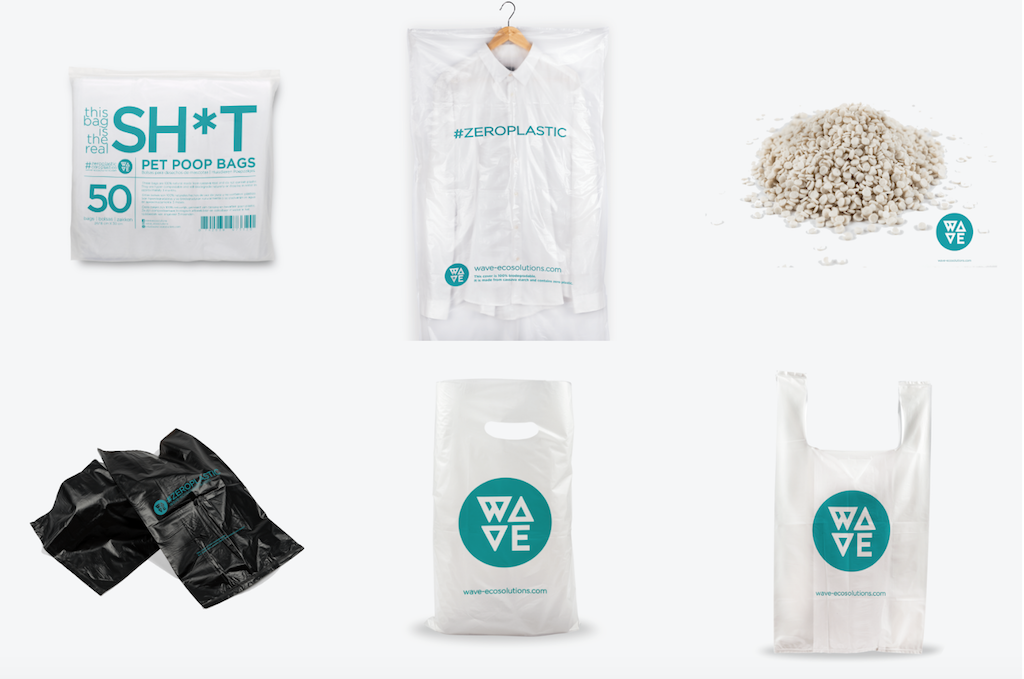

Amsterdam-based startup WAVE Eco Solutions has developed a biodegradable and hot water soluble cassava-based bio-plastic bag in a bid to tackle the global plastic pollution crisis. Unlike conventional plastic bags, WAVE’s products are made without plastic polymers that are typically made using fossil fuels. Their new alternative to plastic does not contribute to greenhouse gas emissions generated by fossil fuel burning, all the while helping to alleviate the plastic waste and offering businesses a concrete, workable solution.

Our planet is currently facing a plastic waste emergency with overflowing landfills and plastic-poisoned oceans. Last month, reports surfaced of microplastics found in rainfall. We’re even consuming plastics that have entered into our food chain and waterways, which can have potentially harmful consequences on our health, prompting the World Health Organisation (WHO) to call for more global research. Plastic waste is engulfing the Southeast Asian region in particular, with many countries struggling to battle the pervasive plastic packaging culture and unwanted plastic imports.

In addition to being a core source of the planet’s pollution crisis, manufacturing traditional plastics require a colossal amount of fossil fuels, which in the process generates climate change inducing greenhouse gases. The plastic industry takes up around 8% of global oil production, and with increased demand is projected to rise to 20% by 2050.

Whilst living in Asia for over a decade, WAVE founders Roberto Guzmán and Malou Claessens experienced first-hand the scale of plastic waste crisis throughout the region. The duo, who spent many years in Vietnam and China, were compelled to create an 100% plastic-free plastic alternative. Instead of using petroleum oil or natural gas to manufacture, WAVE products do not rely on fossil fuels because they are made from a bio-based polymer compound. In this case, WAVE uses natural cassava starch, one of the most abundant resources in nature. The crop is predominantly rain-fed and thus not resource intensive, making it a sustainable alternative ingredient to traditional plastic polymers.

The natural cassava starch based plastic alternative is fully biodegradable and compostable. It is instantly dissolvable in water at temperatures of 80 degrees celsius and higher, and will also naturally decompose in cold water within 3 months, leaving behind non-toxic drinkable water. WAVE products will also naturally compost in soil or landfills within 3 to 6 months.

Despite WAVE products being much more sustainable than traditional plastic, it does not sacrifice on the practical front. The zero-plastic product can carry up to 9 kilograms, making it a suitable replacement for many single-use items that are currently on the market in the food packaging and retail industry.

Elsewhere in Asia, a 23 year old Filipino scientist Denxybel Montinola has also come up with a solution for the global plastic waste emergency. He has combined the fight against plastic with another environmentally friendly mission to reduce food waste, creating a new blend of bioplastic with two biopolymers, pectin and carrageenan found in locally available mango peels and seaweed.

Images courtesy of Wave Eco Solutions.