Orbillion Bio’s New Partnership Will Produce 4 Million Pounds of Cultivated Meat Per Year

3 Mins Read

Collaborating with synbio tech solutions provider Solar Biotech, cultivated meat pioneer Orbillion Bio says it can produce upwards of four million pounds of cultivated meat per year.

Known for its premium cultivated Wagyu beef, California-based Orbillion Bio says the new partnership with Solar Biotech will see it scale up to 20,000L bioreactors — enough to produce more than four million pounds of cultivated meat per year.

The announcement follows the recent FDA GRAS status for Upside Foods’ cultivated chicken, moving the cultivated meat industry closer to U.S. regulatory approval.

In position for mass production

The partnership is the first of its kind for Solar Biotech, marking its official entry into the cultivated beef industry, following its launch into animal-free chicken and work with Motif Foodworks on a yeast-derived heme protein.

“At Solar Biotech, we develop world-class bioprocessing technology together with leading players in biotech. We now want to bring our knowledge and decades of experience into creating real impact in the sustainable food tech space, and there is no better partner than the Orbillion Bio team. We see our technical synergy with Orbillion as an opportunity to enter a rapidly growing higher value cellular agriculture segment, which will yield long-term significant recurrent revenue for both parties with attractive profit margins” Alex Berlin, CEO and CTO of Solar Biotech, said in a statement. “They bring significant expertise in world-class bioprocessing and food, and we are looking forward to investing in this partnership to bring cost-effective and nutritious foods to market.”

The partnership marries Orbillion’s proprietary cell culture platform with Solar Biotech’s scale-up bioprocess development capabilities and infrastructure, proprietary AI-driven bioprocess controlling software, new biosensing technologies, and vertically integrated engineering, and previous experience commercializing mammalian cell cultures for animal-free meat, the companies said in a statement.

Quality, parity, and sustainability

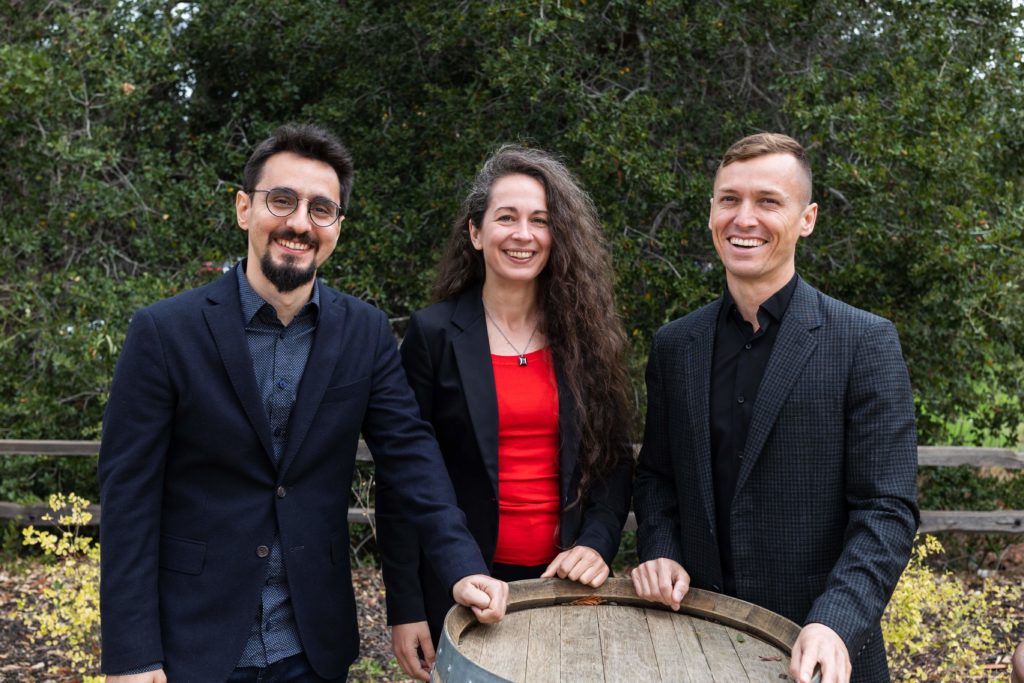

“Orbillion’s innovative business model will bring to market the highest quality cultivated beef, while being cost competitive,” Patricia Bubner, CEO of Orbillion, said in a statement. “Our unique technology has already allowed us to produce meat that comes from non-GMO cells and that is free of fetal bovine serum (FBS), and by partnering with Solar Biotech we can move more swiftly to reach price parity.”

The new partnership will see Orbillion produce its meat at lower costs — part of its commitment to achieving price parity with conventional meat by 2026, and commodity pricing for beef by 2030.

It will also help tackle the food industry’s emissions. Orbillion says if produced using renewable energy, cultivated meat could reduce global warming impacts by between 85 and 92 percent versus conventional beef. Lab-grown meat also reduces the amount of land needed to produce protein, and requires fewer resources including fresh water.

As the cultivated protein sector positions itself for widespread regulatory approval, Orbillion hope it is setting itself apart with a focus on premium meats. In addition to its Wagyu beef, it’s also developing elk and lamb meat. A recent partnership with Luiten Foods will bring its range of cultivated meats to Europe by 2025, pending regulatory approval.