‘Healing People and the Planet’: Triplebar Secures $20M to Expand Biomanufacturing Platform for Precision Fermentation and Cultured Proteins

6 Mins Read

Green Queen talks to Californian biotech startup Triplebar’s CEO Maria Cho about how the company’s product design engine helps make precision fermentation and cultivated meat proteins more scalable and more affordable on a shortened timeline.

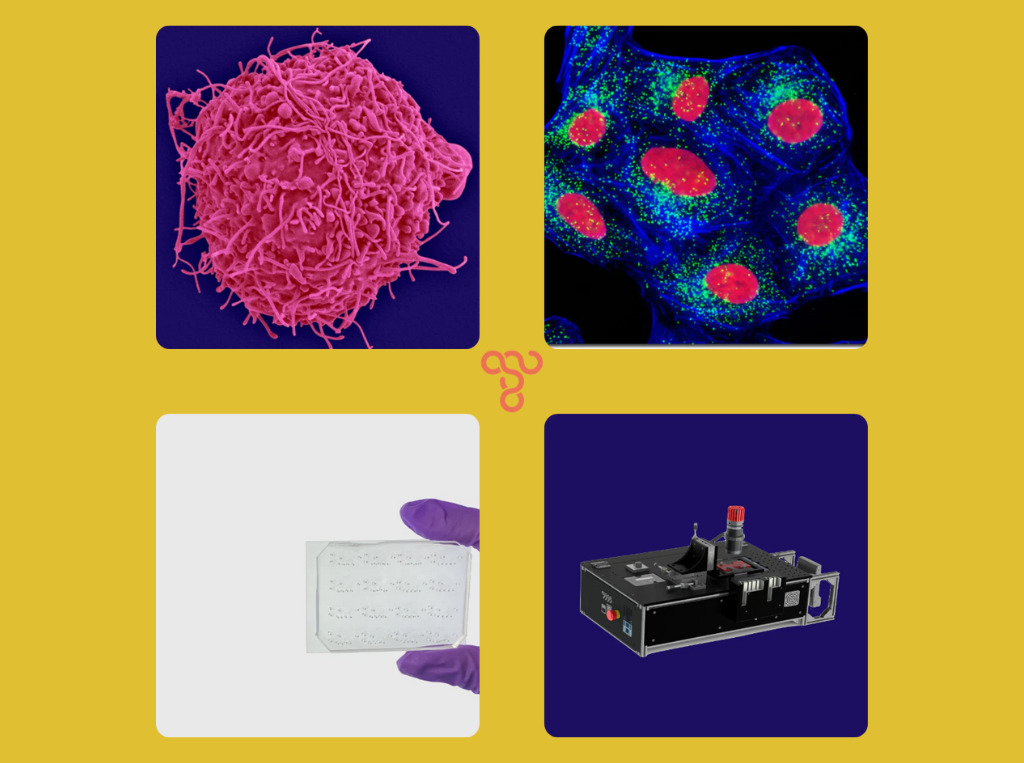

Powered by AI and machine learning, Triplebar has closed a $20M funding round to expand its biomanufacturing platform and portfolio in food and pharmaceuticals. The company has developed a high-throughput screening platform that combines microfluidics and hyperspeed testing with AI and machine learning to develop biomanufacturing platforms for microbial or animal cells. It’s described as a “microprocessor for biology”, which integrates hardware, software, biology and biochemistry to miniaturise and accelerate evolution.

Its latest $20M investment round, which takes total funding to $25M, was led by Synthesis Capital, with participation from Essential Capital, Stray Dog Capital, iSelect Fund, and existing investor The Production Board. Triplebar is a foundry business of the latter, the startup’s first and major investor.

“For truly disruptive adoption to take place, alternative products need to at least match animal-based proteins on taste, price, convenience, and nutrition,” said Synthesis Capital co-founder and partner Rosie Wardle in a statement. “We believe Triplebar’s technology platform has the potential to bring entire portfolios of bioproducts to market, helping a wide range of companies, from incumbents to startups, to scale up production while reducing cost.”

An advanced platform for alt-protein production

Triplebar works on two kinds of animal proteins, derived from precision fermentation (via yeast or bacteria) and cell cultivation. For the former, it focuses on bioactive proteins that provide health benefits when consumed, but whose natural source (dairy or otherwise) constrains the supply and limits access to this ingredient,” explains Cho. “We make the production system that allows for low-cost, animal-free scaling of these ingredients to provide access for everyone.”

As for cultivated meat, the startup addresses a key bottleneck: the evolution of animal cells so they can grow effectively in a fermentation vessel similar to those used for brewing beer. “Once this is achieved, critical barriers associated with cost and production volume can be overcome,” says Cho.

A growing number of companies are using synthetic biology – already a $13.4B market – to create alt-proteins. Boston-based Ginkgo Bioworks provides its cell-programming platform to a host of startups, for example. What advantage does Triplebar provide? “Triplebar makes it possible to use evolutionary design to optimise the cell lines (bacterial, fungal or animal) that are the foundation of alt-protein technology,” explains Cho.

A biotech veteran and a biochemist by training, Cho has amassed over 15 years of experience building industry-leading teams in industries such as therapeutics and cosmetics. In 2019, Cho founded Phage microbiome product company Phi Therapeutics, which debuted the Phyla™ system- the first-ever probiotic skincare range.

“We do this by dramatically increasing test throughput compared to other methods, allowing us to scan every base pair every day in an entire genome of these cell lines for improvements that occur randomly. This rapid cycle of insight-free improvement builds on itself exponentially to quickly deliver cell line performance that makes alt-protein products affordable and scalable.

“By contrast, traditional methods have a test throughput three or four orders of magnitude less than ours, meaning these methods rely on [a] poor understanding of how cells work to make progress. This traditional route is slow and expensive, leading to the incredibly high capital barrier and low success rate of alt-protein products getting to market historically.”

Solving the cost and speed issues

Triplebar boasts a much faster rate of testing and discovery. “Because we can look at every base pair in a genome in a day, we can find improvements quickly and do so without relying on humanity’s incomplete understanding of how organisms actually function,” notes Cho. “This means that we can hit performance targets in months that would normally take years.”

Additionally, the startup claims its platform can develop biological systems that enable low-cost manufacturing, another bottleneck of the alt-protein sector. “We make progress using evolutionary design, which does not rely on a rational understanding of how a cell works. This means that we can optimise a cell to be maximally efficient at producing a protein regardless of the cell type or protein,” says Cho.

“This maximal efficiency translates to a low-cost production system for precision fermentation or cultivated meat. It also means that cell lines can be evolved to fit into current at-scale processes, reducing process innovation requirements that impact cost and timeline to scale.”

She adds that cellular agriculture faces a host of issues, including cost, taste, consumer acceptance and scale. A 1,018-person survey commissioned by the Good Food Institute found that 45% of respondents are willing to try cultivated meat once explained to them. Meanwhile, a 1,930-person poll by the UK Food Standards Agency – the body responsible for regulatory approval of these proteins – found that only a third (34%) of Brits are open to eating cultured meat, with only 30% considering it safe.

“We help companies find the right cell lines with which to make their products,” says Cho. “The right cell line makes a massive contribution to cost and scale, and can even have impacts on taste and consumer acceptance.”

Collaborations and ultimate mission

Triplebar has established multiple undisclosed partnerships with manufacturers across sectors like food, healthcare and more. Two prominent publicly known collaborations are with Singaporean cultivated seafood producer Umami Bioworks and global ingredients giant FrieslandCampina Ingredients (FCI).

With Umami Bioworks, Triplebar is co-developing optimised cell lines suited to large-scale production of cultivated seafood, starting with one of the most critically endangered fish species, Japanese eel. The link-up will include improving the “fitness and performance” of cell lines to enable lower-cost, more efficient manufacturing of cultured proteins.

Umami Bioworks will leverage Triplebar’s ‘Hyper-Throughput’ platform to discover solutions, testing “millions of potential phenotypic solutions in the time it normally takes to search mere hundreds” to accelerate cell line development and optimisation without the need for genetic modification.

The FCI partnership focuses on bringing multiple protein ingredients to market via precision fermentation, a technology it has been using since 2016 to produce human milk oligosaccharides. The collaboration with Triplebar involves multiple programmes, including many elements “like product testing, strain engineering, scale-up manufacturing, regulatory approval, and commercialisation”, says Cho. “So we will be working with them for years. We are thrilled to partner with FCI to make a lasting impact on the way protein ingredients are produced.”

By helping companies release low-cost products that change our food system’s impact on the climate and human health, Cho says the startup’s mission is to “feed and heal people and planet”. “We envision a future where a mature bio-economy can deliver to humanity products that allow us to live sustainably at scale,” she adds.

“This mature bio-economy, like other mature markets, is an ecosystem where companies work together in stratified supply chains to increase the flow and value of products to consumers. We want to play our part in the mature bio-economy and enable others to do the same.”