5 Mins Read

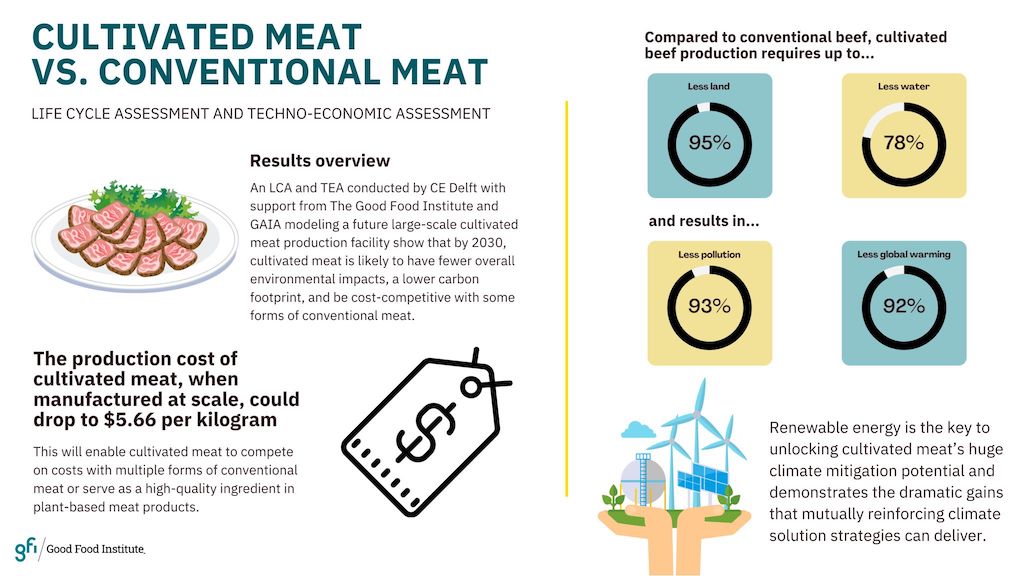

The far reduced climate impact of cell-based meat has been revealed in a new first-of-a-kind life cycle assessment published by the alternative protein nonprofit Good Food Institute (GFI), showcasing that proteins cultivated directly from cells can save up to 92% of greenhouse gas emissions, in addition to other environmental savings. In a separate analysis, the GFI also projects that cultivated meats could rival the price of its conventional counterparts as soon as 2030, a milestone that experts describe as a critical turning point to the mass adoption of sustainable protein alternatives.

Released on Tuesday (March 9), new GFI research details the importance of cultivated proteins in the race towards a healthier, sustainable food system as part of the global push to net-zero emissions. The research, published as two first-of-a-kind studies, assesses the environmental savings of cell-based protein production compared to meat from traditional animal agriculture by 2030, and estimates the rapid timeline for cultivated industry to reach price parity.

In a life cycle assessment conducted by independent research firm CE Delft, researchers project that by the next decade, cultivated meat production powered by renewable energy sources can lead to 92% less impact on global heating, save 93% of particulate matter pollution, and requires 95% less land and 78% less water compared to conventionally farmed cattle-based beef. These figures were calculated using data collected from more than 15 companies across the cultivated meat supply chain, including five manufacturers.

Read: 10 reasons why cultivated meat is the future of protein

As these new models illustrate, if we can concentrate the environmental impact of meat production in a single, manageable space—and if we power that space with electricity generated from clean energy sources—that’s how the world gets to net-zero emissions.

Bruce Friedrich, Executive Director, GFI

One of the most significant factors underpinning the sustainability advantages of cell-based protein production by 2030, according to the research, is the transition to clean energy sources, efficient cell culture media and facility capital costs. But the analysis used conservative modelling for energy use for the cultivated industry, while also using ambitious best-practice benchmarks for conventional meat production, suggesting that the likely environmental savings of meat produced directly from cells could be even higher.

“The results from this conservative comparison indicate that the observed environmental benefits of cultivated meat in the life cycle assessment are expected to be highly robust,” wrote the researchers.

“Decarbonising the global economy is impossible with the diffuse production process and range of gases involved in conventional animal agriculture. As these new models illustrate, if we can concentrate the environmental impact of meat production in a single, manageable space—and if we power that space with electricity generated from clean energy sources—that’s how the world gets to net-zero emissions,” commented Bruce Friedrich, executive director of GFI.

Mirte Gosker, acting managing director of GFI Asia Pacific (GFI APAC), added that the findings should further bolster governments’ push for alternative proteins like cultivated meats as a central part of their carbon neutral strategies, which Singapore is pioneering with its supportive infrastructure for the burgeoning sector.

“Cultivated meat can help governments in Asia Pacific fulfil net-zero emission pledges, while also enhancing food security and creating new high-paying job opportunities,” said Gosker. “Singapore’s bold efforts to accelerate alternative proteins at every stage from R&D to regulation and distribution have created a model for success, but global issues require global solutions, so it’s time for other governments around the region to wake up and embrace this better way of making meat.”

Cultivated meat can help governments in Asia Pacific fulfil net-zero emission pledges, while also enhancing food security and creating new high-paying job opportunities.

Mirte Gosker, Acting Managing Director, GFI APAC

In a separate techno-economic analysis, researchers considered the expenditures and operating costs of cell-based meat production, and projected that such proteins could become cost-competitive with conventional meat at a price of US$5.66 per kilogram by 2030 in the “best-case scenario”. Much of the reduced costs will come from efficient use of food-grade media, dramatic cuts in the cost of producing growth factors and recombinant proteins, and relaxed payback times for capital expenditures.

Perhaps the most important factor that will contribute to the race to price parity, according to the assessment, will be cheaper cell culture medium, which the study says currently accounts for as much as 99% of the baseline production cost. In particular, the recombinant protein albumin, which is the most abundant protein in animal serums, is responsible for anywhere between 80% to 95% of the total recombinant protein costs for manufacturers.

While the “best-case scenario” prediction of price parity by 2030 appears to be wildly ambitious to some skeptics, the study emphasises that these modelled estimates “could reasonably be expected”.

As soon as 2030, we expect to see real progress on costs for cultivated meat and massive reductions in emissions and land use brought about by the transition to this method of meat production.

Elliot Swartz, Senior Scientist, GFI

“Importantly, the modeled price reductions of 1000X for growth factors and 100X for recombinant proteins may seem excessive but are actually conservative,” said the report. “These price reductions bring the costs to approximately ~$3M per kg of growth factors and $1000 per kg of recombinant proteins. It is well-documented that industrial proteins produced at scale often have prices in the tens of dollars per kg.”

Elliot Swartz, senior scientist at GFI, described the findings as a “vote of confidence” for the cultivated meat industry.

“As soon as 2030, we expect to see real progress on costs for cultivated meat and massive reductions in emissions and land use brought about by the transition to this method of meat production,” Swartz continued. “This research…serves as a practical roadmap for the industry to address technical and economic bottlenecks, which will further reduce climate impacts and costs.”

Lead image courtesy of Memphis Meats.