Liberation Labs Gears Up for $75M Series A to Fund Facility As Industry Doubles Down on Production

6 Mins Read

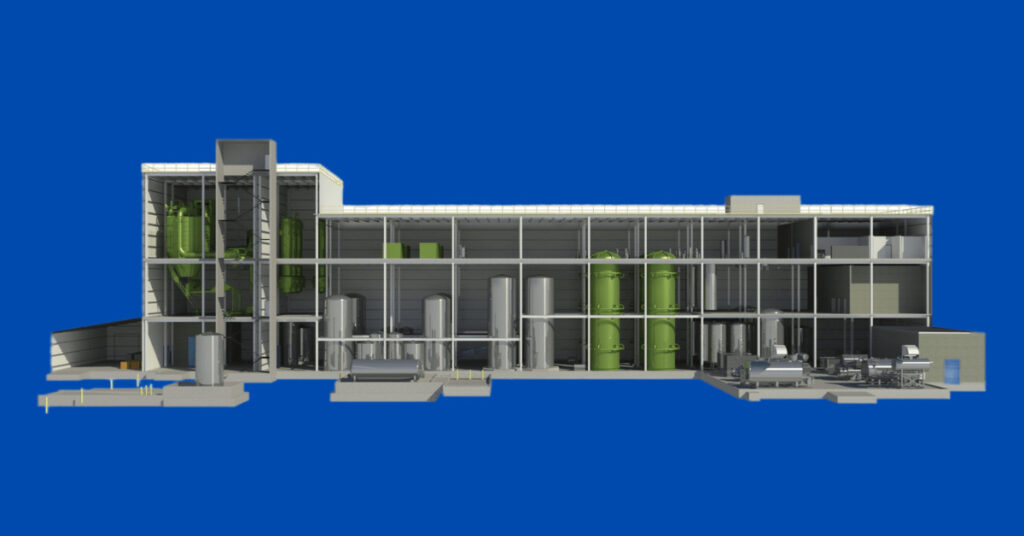

US precision fermentation protein manufacturer Liberation Labs is lining up a Series A funding round that could ink the brand as much as $75M, reports Axios. The financing will be used to build its upcoming $115M facility in Richmond, Indiana, which will have a capacity of between 600 to 1,200 tonnes of protein per year.

Months after it secured $30M in equipment financing for its biomanufacturing plant, which it broke ground on in June, Liberation Labs CEO Mark Warner told Axios that the company’s Series A funding will largely be equity, but could involve more equipment financing or even government investment.

He added that investors could include traditional VC firms as well as infrastructure and climate funds, and the funds may end up being a blend of debt and equity. The Series A round is set to close by the end of the year and could bring its total funds raised to $126M (including a $20M seed round last year and a $1M funding round).

Building commercial-scale facilities across the globe

Liberation Labs will use the cash to fund the Richmond plant, which is a commercial-scale facility built to meet the growing demands of proteins from precision fermentation. The factory – which is set to cost around $115M and become operational sometime next year – will be capable of producing between 600 to 1,200 tonnes of protein annually, and bring in $40M in yearly revenue.

Warner previously told AFN that the plant will have downstream processing capabilities and support clients ranging from well-funded precision fermentation startups to established ingredient firms and CPG companies: “Our facility in Richmond will be the first fit-for-purpose precision fermentation food protein manufacturing facility in the world, to my knowledge.”

If all goes well, the company will then look to build another factory five times the size of this one, which is estimated to generate $160M in revenue each year and will be funded via more traditional project financing. “Long term, we’re looking at six geographies worldwide,” Warner told AFN in April. “In each one, we expect to build initially a 600,000-litre launch facility, and ultimately a four-million-litre commercial facility.”

“This type of company and industry is a perfect fit for the Hoosier state given Indiana’s strong agriculture and manufacturing sectors,” Indiana Governor Eric Holcomb said in a statement. “We love to see innovative new technologies creating quality jobs and career pathways for both today’s and tomorrow’s workforce.”

Reducing costs for futureproof proteins

Warner told Axios that while billions have been poured into working out how to produce cell-cultivated proteins, scale remains a question mark. With precision fermentation, that isn’t as much of a challenge, as it can already be scaled up. “Despite strong consumer interest in bio-based ingredients, the industry has yet to fully deliver on their promise,” Warner said in a statement after breaking ground on the Richmond facility.

Liberation Labs aims to address the capacity bottleneck and lower the costs attached to precision fermentation. “Something like lactoferrin, which has a high dollar value, is certainly attractive, but once you get to the 50 to 100 bucks a kilo range, that’s where it starts to get difficult,” he told AFN. “Really, anything that currently sells for less than 50 bucks is a challenge, although it also depends on how much you use in a given application.”

He added: “As you really get into what I would consider bulk products, there’s going to need to be additional development on the process to reach viability.”

Independent life-cycle assessments carried out on behalf of precision fermentation dairy companies Perfect Day and Bon Vivant found that their animal-free whey proteins have 99% less water use and 97% lower emissions than conventional dairy. And non-company assessments have found that precision-fermented proteins can have a 53-100% lower environmental impact than animal-based proteins.

Touching upon these futureproof aspects, Warner said in June: “We believe our purpose-built biomanufacturing facility will fill the gap and help usher in a new era of advanced bioproducts that will make our lives better, including foods, materials and yet-to-be-discovered breakthroughs.”

Funding and facilities for fermentation

The global fermentation sector has raised about $3.7B in total funding, with over $840M coming in just last year, according to industry think tank the Good Food Institute. It reports that there are at least 62 companies working in the precision fermentation segment across the supply chain, including Perfect Day, Formo, Remilk, Imagindairy and Aqua Cultured Foods.

In terms of production facilities, Remilk – which is worth $325M after a $120M Series B round in January 2022 – had broken ground on what it described as the “world’s largest full-scale precision fermentation facility last year but has put construction on hold for now as it focuses on increasing production at its existing plant. Meanwhile, fellow Israeli company Imagindairy has secured a total of $28M in seed funding so far.

In the UAE, American-Australian producer Change Foods – which has secured $15.3M in total funding – signed an agreement last year to design a first-of-its-kind commercial manufacturing plant, with a capacity of 1.2 million litres.

In Australia, Cauldron Foods raised AU$10.5M ($6.74M) earlier this year to build Asia-Pacific’s largest network of precision fermentation facilities. Fellow Aussie company All G, meanwhile, reeled in $25M in a Series A round last year to take its total funding to $40M. Meanwhile, China’s Changing Biotech secured a $22M Series A round last year and is building a 9,000 sq m facility in Qingdao – its current facility has a capacity of five tons, and it’s working on designing six 50-ton lines.

In India, Sterling Biotech was acquired by Perfect Day last year, which took over its three facilities across the country. The company, which has raised a total of $750M and was worth $1.5B in 2021, has plants in Berkeley and Salt Lake City (60,000 sq ft), and in addition to the Indian factories, it has four commercial-scale co-production facilities globally, giving it the capacity to produce thousands of tonnes of its animal-free whey protein.

Elsewhere, German precision-fermented company Formo, which recreates egg and dairy proteins, raised a record-breaking $50M in Series A funding in 2021 to bring total financing to $54.7M, while Californian counterpart The Every Co closed an oversubscribed $175M Series C round the same year.

Meanwhile, New Culture, which produces precision-fermented casein, is the only company that has claimed it can manufacture animal-free casein at scale, with the capacity to produce up to 25,000 pizzas’ worth of cheese with each batch of its protein.

Earlier this month, Aussie producer Eden Brew, which has developed what it calls a “world-first” animal-free casein micelle, closed a $24.4M Series A funding round. Just today, French precision fermentation company Bon Vivant (which works on both whey and casein) announced a €15M ($15.9M) seed round to accelerate the production of its beta-lactoglobulin protein.