4 Mins Read

South Korean startup SeaWith has set its sights on bringing cultured meat to diners by the end of next year. The firm has already developed its own seaweed-based cell culturing medium and scaffolds, and is now in the process of scaling up production ahead of its plan to unveil its final cultivated meat products at a pilot restaurant.

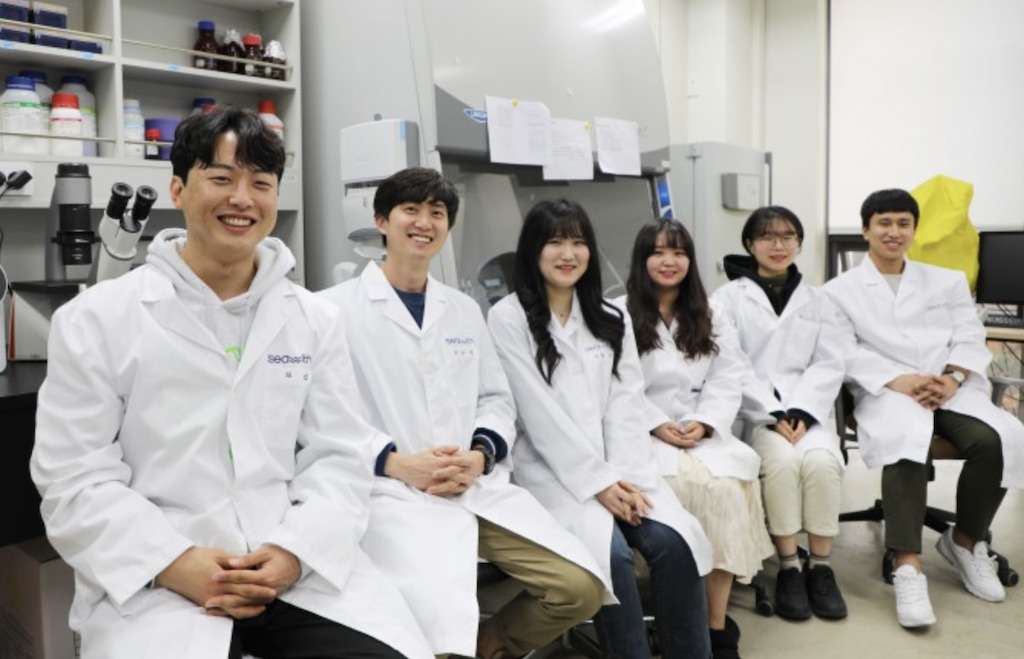

Founded two years ago by Joonho Keum and Heejae Lee, who came together during their PhD studies at the Daegu Gyeongbuk Institute of Science and Technology (DGIST), SeaWith is a homegrown South Korean food tech with ambitious plans to revolutionise the country’s protein production.

While South Korea’s plant-based meat industry is steadily growing, with big players like Pulmuone entering into the space alongside vegan startup brands like Unlimeat, SeaWith wants to make real animal meat – but without the animals. At their base in the metropolitan city of Daegu, the company is using cellular agriculture to culture slaughter-free steaks that will hopefully convince even the hardiest meat-lovers to turn away from its conventionally farmed counterparts.

By doing so, SeaWith hopes to disrupt the livestock industry and its enormous environmental footprint, from the huge amounts of greenhouse gas emissions it releases, to the overuse of crucial planetary resources like land and water.

But one problem standing in the way for SeaWith and the rest of the cultivated protein industry when it comes to mass consumer adoption is cost – and currently, culturing meat is an expensive process.

To tackle production costs, SeaWith has been working on developing their own materials that are necessary for cell-based meat production – cells, scaffolds and culturing media. And they’ve managed to do it using the regionally abundant and cost-efficient seaweed, which offers an additional benefit of being completely plant-based and cruelty-free, as opposed to the existing expensive and non-animal-free use of fetal bovine serum (FBS).

According to the firm, their microalgae-based cell-culture medium is already able to replace more than 80% of FBS usage at current levels. Already inexpensive to produce, the startup says that they are likely going to keep cutting costs even further as they scale mass production of their microalgae materials.

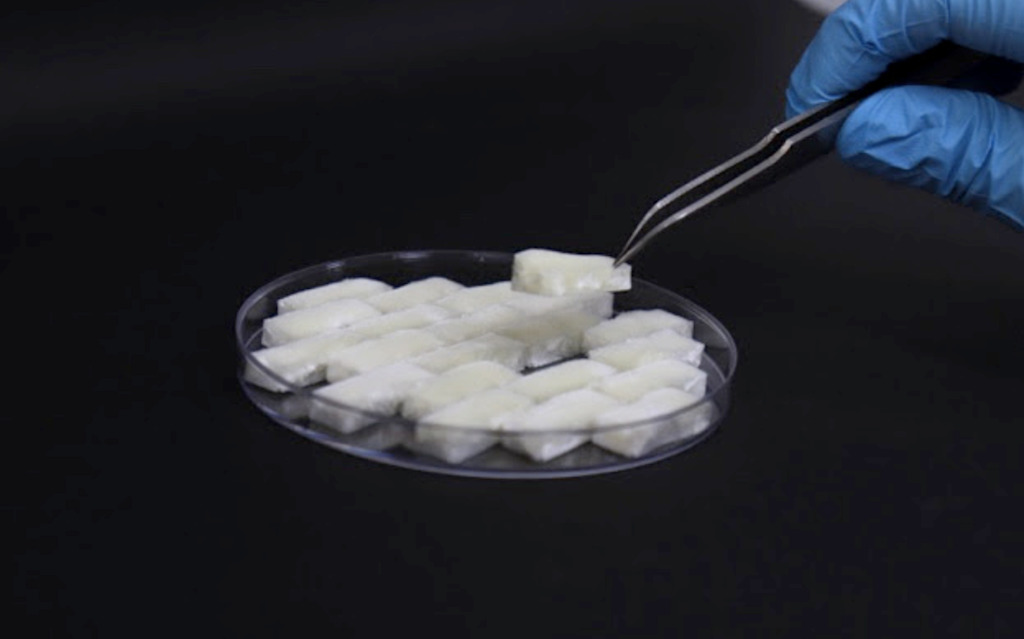

Once the cells are feed nutrients to begin growing in the media, SeaWith gives cells their own algae-based 3D scaffold dubbed “Ace-Gel” to allow the cells to begin multiplying, growing and forming a thick tissue structure. After incubating the cells with the scaffolding, SeaWith says they are able to produce a cultured meat prototype that mimics the thickness and texture of a cut of steak.

Their technology has already won them ₩500 million (approx. US$450,000) from South Korean early-stage tech startup investors Bluepoint Partners and Enlight Ventures, and has been handpicked to join the country’s government-backed Tech Incubator Program for Startups (TIPS).

While the startup’s cultivated meat product is still in R&D stage, the team has already set an ambitious timeline for commercialisation. By the end of 2022, SeaWith hopes to have scaled their technology and manufacturing capabilities to be able to present their first cell-based meats to consumers at a pilot restaurant, ahead of a commercial launch if they manage to climb over regulatory hurdles.

If they manage to do so, SeaWith could be among the first in the country to launch a cultivated protein product to diners. So far, only San Francisco-based Eat Just has managed to gain regulatory approval from Singapore authorities to sell their cultured chicken on the market in a world’s first in December 2020.

Other homegrown food techs in the running in South Korea include CellMEAT, who recently closed ₩5 billion (approx. US$4.5 million) in a pre-Series A funding round, which will go towards developing its FBS-free cultured meat and lowering costs.

DaNAgreen, who has adapted its initial biomedical scaffolding for cell-based meat production and at a price “a thousand times cheaper than the original”, says that they are now in the process of creating an entire platform for cellular agriculture protein production, from culture media to bioreactors.

All images courtesy of SeaWith.