4 Mins Read

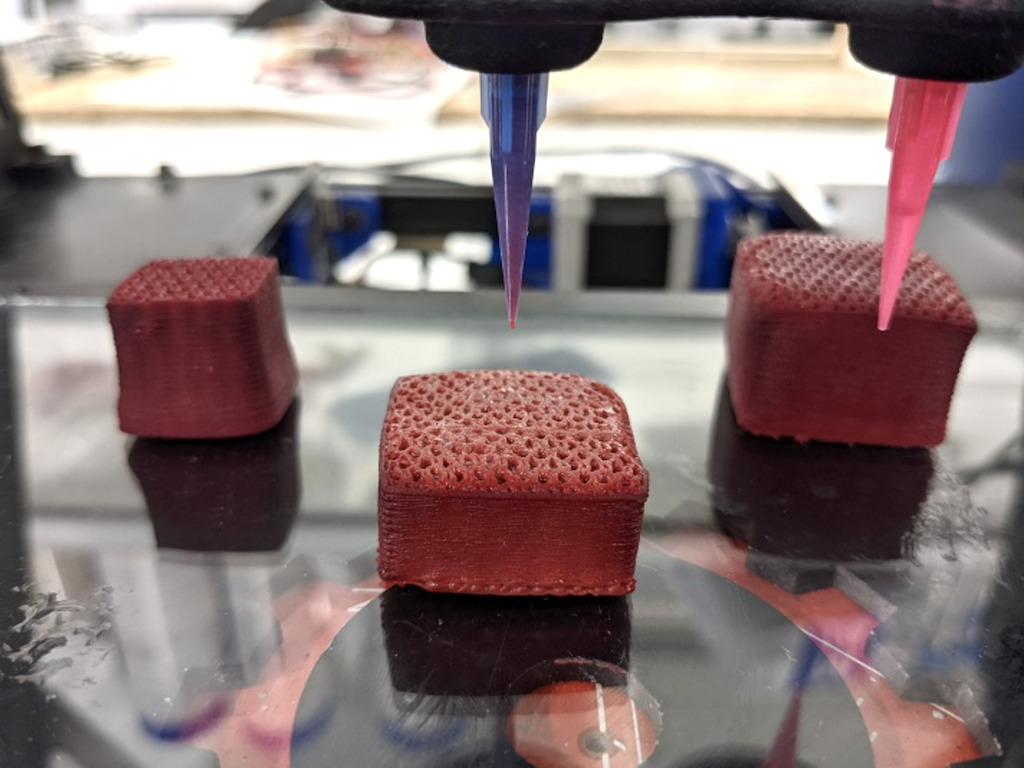

Novameat has developed what it bills as the “world’s biggest cell-based meat prototype” to date, the Spanish food tech revealed in a recent interview. Speaking to FoodNavigator, Novameat’s founder and CEO Giuseppe Scionti says that the firm’s ability to 3D print whole cut meats could present a “complete gamechanger” to disrupt the unsustainable meat industry.

Barcelona-based food tech Novameat has managed to produce what it calls the largest whole cut cultivated meat prototype in the world. The startup, who have previously created 3D-printed plant-based meats and a vegan-friendly “steak” using its patented microextrusion technology, recently spoke to FoodNavigator about its latest developments.

“Our biggest cell-based meat prototypes – or you can call them hybrid meat analogues, as we mix mammalian adipose cells with a biocompatible plant-based scaffold – score at 22500mm³ in volume,” Novameat founder and CEO Scionti told the publication.

“I am really looking forward to the next few months, because if our technology is able to unlock the whole cut market, this can be a complete game-changer for the alternative meat industry.”

Our biggest cell-based meat prototypes – or you can call them hybrid meat analogues, as we mix mammalian adipose cells with a biocompatible plant-based scaffold – score at 22500mm³ in volume.

Giuseppe Scionti, Founder & CEO, Novameat

Novameat says that it decided to take a hybrid approach to alternative proteins in order to have the most disruption on the unsustainable meat supply chain, and that using both plant-based and cell-based technology would allow them to overcome key obstacles that the cultivated space continues to face.

“If we really want to see cell-based meat competing on price with conventional meat, there are a few technological limitations that need to be solved,” Scionti explained.

Among some of the hurdles he cited include finding alternatives for animal-based cell media and fetal bovine serum (FVS) to finding affordable scaffolds – though there are an emerging cohort of startups now working on these issues, such as Seoul-based DaNAGreen, Matrix Meats in Ohio, Perth-based Cass Materials and Tiamat Sciences headquartered in Brussels.

In addition, Scionti believes that current alternative proteins already on the market, such as plant-based burgers and sausages, or Eat Just’s cell-based chicken bites that is for now the only cultivated product commercially available, have yet to provide alternatives for whole cuts of meat that are realistic in taste, texture, bite and experience to real animal meats – and that hybrid plant-based and cell-based products could be key to addressing this.

If we really want to see cell-based meat competing on price with conventional meat, there are a few technological limitations that need to be solved.

Giuseppe Scionti, Founder & CEO, Novameat

“Meatballs, burgers, nuggets and thin slices of whole cuts have already been done. But if I were going to a high-end restaurant – where I expect cell-based meats to be sold in the next few years – to try cell-based meat, I would prefer to try a thick cell-based Kobe Wagyu beef or an expensive seafood. And I don’t see much advances in that sense yet,” said Scionti in the interview.

Other startups that are banking on this hybrid approach include Moolec Science, who say their method will be “10 times more cost-efficient”, and Israeli firm Meat-Tech 3D, who acquired cell-based fat platform Peace of Meat to launch products that incorporate both plant and cell-based ingredients and speed up its route to commercialisation. British food tech Higher Steaks have also debuted hybrid prototypes of pork belly and bacon.

Novameat, although perhaps the first to debut a large chunk of meat, isn’t alone in the race to develop prototypes of realistic cultivated cuts of meat that can replicate the muscle and fat tissue of its animal counterparts either.

Recently, researchers from McMaster University detailed in an academic paper their novel method of producing cultivated meat by stacking thin layers of cells that have been cultured from labs into a final product that resembles whole “slabs of meat”.

Meanwhile, Eat Just, after launching the world’s first commercially sold cultured chicken bites, said it intends to accelerate R&D into cell-based proteins at its Singapore global manufacturing hub for its Good Meat brand, with its next step being to create more “highly texturised” chicken meats within the next two to three years before taking it to another level and culturing the bones, wings and cartilage of animal meat too.

Lead image courtesy of Novameat.