Liberation Labs Raises Further $12.5M to Support Construction of Precision Fermentation Facility

5 Mins Read

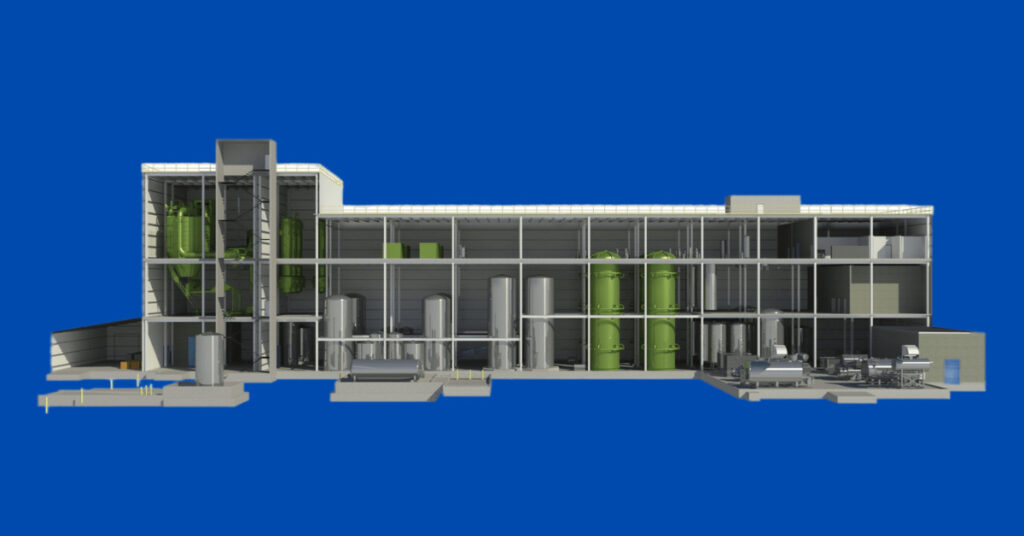

US biotech manufacturing firm Liberation Labs has secured $12.5M in funding to support the ongoing construction of its large-scale production facility in Indiana, ahead of its Series A round.

Liberation Labs’ latest capital injection of $12.5M will advance the building of its manufacturing plant in Richmond, Indiana, which is intended to serve an increasing demand for proteins made via precision fermentation.

Food tech VC firm Agronomics – which now holds a 37.5% stake in the company – invested $10M in this round, with additional funding from existing investor Siddhi Capital. It brings the total equity-linked financing in Liberation Labs to $33.5M, and the company additionally has non-dilutive funding commitments totalling $55M – this includes $30M in equipment financing and a $25M USDA-backed loan.

The investment will convert on the same terms as Liberation Labs’ upcoming Series A round, which is expected to raise a minimum of $37.5M and support the continued constriction of its Indiana plant.

“The new funding from Agronomics and Siddhi Capital comes as we continue to make significant progress in building out our operations team and advancing facility construction – including the installation of key equipment like fermenters and spray dryers,” said Liberation Labs co-founder and CEO Mark Warner. “Each day, we’re closer to our goal of unlocking the potential of domestic manufacturing of novel proteins for both food and industrial use.”

Liberation Labs aims to open facility in early 2025

Founded in 2022, Liberation Labs aims to commercialise precision-fermented ingredients via a global network of purpose-built manufacturing facilities to produce bio-based products at scale, with a fit-for-purpose design that can enable cost-effective solutions.

Its factory in Richmond, which is expected to cost around $115M, will be capable of producing between 600 to 1,200 tonnes of protein annually, and bring in $40M in yearly revenue. It will have downstream processing capabilities and support a variety of clients, from well-funded precision fermentation startups to established ingredient and CPG companies.

If things go well, the company will also look to build another factory five times greater in size, with the potential to generate around $160M in annual revenue (this will be financed via more traditional project financing). “Long term, we’re looking at six geographies worldwide,” Warner told AFN last year. “In each one, we expect to build initially a 600,000-litre launch facility, and ultimately a four-million-litre commercial facility.”

The company is hoping to address the precision fermentation industry’s capacity bottleneck through the design, build and operation of its purpose-built biomanufacturing platform, Bio3. The Indiana facility is about halfway through its construction and – provided that Liberation Labs secures the targeted Series A funds – is expected to be operational by Q1 2025.

It chose Richmond as a location due to several key factors, including access to sugar inputs, utility rates, cost and availability of labour, the regulatory environment, and the availability of government incentives. “This type of company and industry is a perfect fit for the Hoosier state given Indiana’s strong agriculture and manufacturing sectors,” Indiana Governor Eric Holcomb has previously said. “We love to see innovative new technologies creating quality jobs and career pathways for both today’s and tomorrow’s workforce.”

Speaking about the latest investment, Agronomics executive chairman Jim Mellom said: “Liberation Labs continues to deliver on the project milestones of its launch facility in Indiana. We have huge confidence in the team’s ability to execute and believe that Liberation Labs will become the first company in Agronomics’ portfolio to be cash-generative.”

A big year for precision fermentation

Liberation Labs’ raise comes at a time when precision fermentation is progressing rapidly in the US and internationally, whether it’s product launches, investment rounds or regulatory breakthroughs.

The eventual mainstreaming of this sector was signposted by releases by two of the world’s biggest food companies. Unilever partnered with California’s Perfect Day to use the latter’s precision-fermented whey protein as the base for a new lactose-free chocolate ice cream by Breyers, while Nestlé unveiled an animal-free Better Whey protein powder under its Orgain brand just weeks earlier.

Meanwhile, San Francisco’s New Culture became the first company to obtain self-affirmed GRAS status for animal-free casein in March, just as Dutch startup Vivici earned this certification for its whey protein a month earlier. In January, Israel’s Imagindairy received a ‘no further questions’ letter from the FDA for its precision-fermented whey. Californian startup Oobli has also received the FDA letter for its Oubli Sweet Protein.

There has been a spate of funding announcements in the sector too. Just last week, Finnish precision fermentation egg producer Onego Bio closed a $40M Series A round and announced it expects to achieve self-affirmed GRAS status in the US soon. Perfect Day itself closed a $90M Series A funding round in January, while casein producer Standing Ovation (France) secured €3M and precision fermentation biomanufacturer Cauldron Ferm (Australia) brought in $6M.

Meanwhile, the state of Illinois has committed $600M to its biomanufacturing hub (which focuses on precision fermentation), and in May, the EU will open applications for investments totalling €50M in precision fermentation and algae-based food startups as part of its Horizon Europe scheme.

Plus, Imagindairy unveiled an industrial-scale facility with a 10,000-litre fermentation capacity, Daisy Lab ramped up production for its beta-lactoglobulin whey powder and diversified into lactoferrin protein, Melt&Marble successfully scaled up its yeast-derived fats ahead of a market launch next year, Yali Bio created what it claimed was the world’s first yeast-derived breast milk fat from precision fermentation, and Bond Pet Foods reached a scaling milestone alongside Hill’s Pet Nutrition to develop pet food products.

Clearly, a lot is happening in the precision fermentation sector – and it’s why trade bodies have come together to set a refined definition that provides clarity and distinction from other novel food technologies. Liberation Labs’ funding is the latest in a long list of developments, and one would expect them to continue as the year progresses.